Here’s a summary of the excellent thesis work recently completed by Bryan Nguyen. We tasked Bryan with exploring the viability of using 3D printing as a manufacturing method for our Galin pump design. His work focused specifically on seeing what was possible with this medium, tackling the unique sealing challenges that arise from 3D-printed components.

Through a great mix of hands-on testing and smart design tweaks, Bryan successfully demonstrated that we can achieve a robust external seal, even with the inherent imperfections of the printing process. More importantly, his investigation into internal leakage provided critical data on the current limitations of the technology for our specific application. Bryan's work has given us a clear and invaluable understanding of the possibilities of 3D printing for future development.

3D Printing Galin Pump

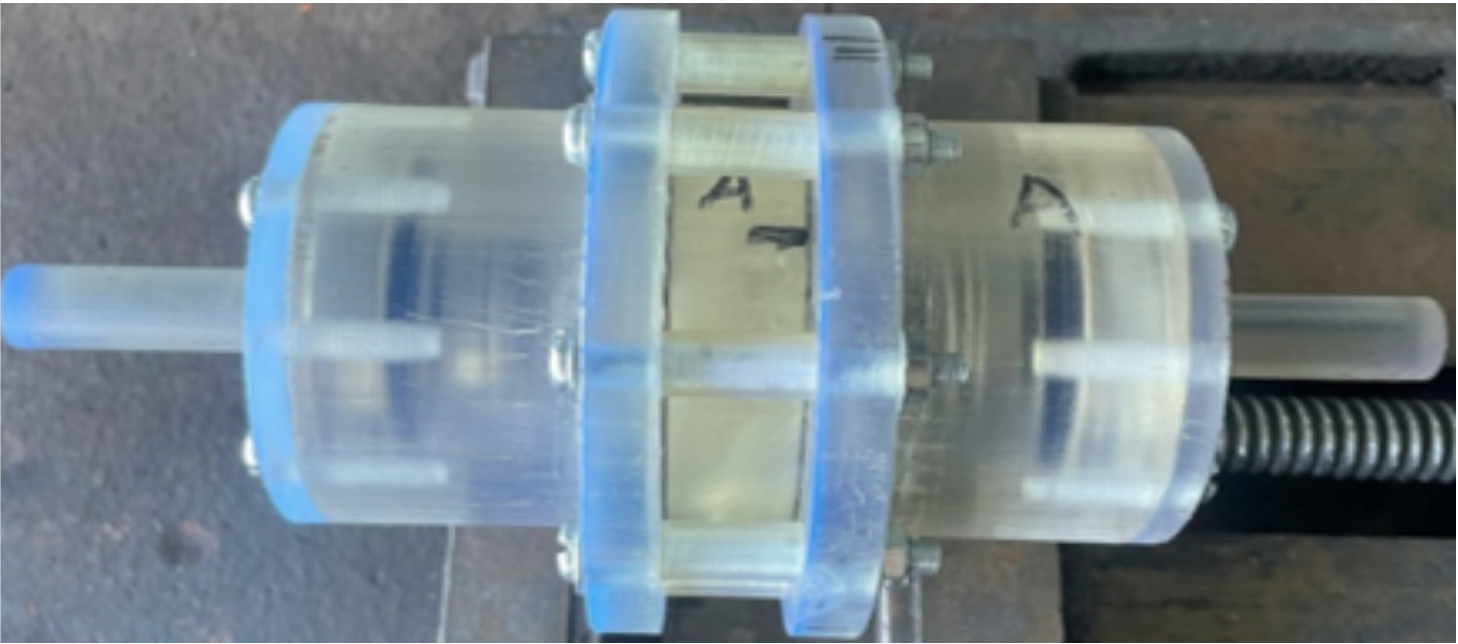

This thesis, completed by Bryan Nguyen at the University of New South Wales for the degree of Bachelor of Engineering (Mechanical), focuses on the optimisation and validation of the 3D printed Galin pump. The work combines mechanical redesign and experimental testing to address critical sealing challenges in the early stages of prototyping the unique Galin pump. A 2D computational fluid dynamics CFD study was also conducted on the Galin pump within this thesis project, to provide an introductory foundation for future CFD work on the pump.

Figure 1 - Initial unpressurised leakage test of the Galin pump using hand operated drill.

The scope of this thesis aims to focus on the ability of the 3D printed Galin pump to ensure effective fluid sealing externally at where the rotating components exit the pump housing and between the pumping chambers.

In depth literature review was conducted on vane and external gear pumps, specifically with how these pumps achieve sealing. Further research was carried out on 3D printing technology which guided the redesign of the Galin pump for stereolithography (SLA) 3D printing, chosen for its superior dimensional accuracy and surface finish.

The optimisation design overhaul incorporated rubber bellows-type mechanical seals, standard in industry for dynamic sealing at where the rotating shafts exit the pump housing. These replaced the original oil ring and bushing setup. The internal clearances between the rotating vanes and the pump housing was set to 0.2 mm based on literature, balancing tight sealing with SLA print tolerance limitations. Once printed and post-process, the pump was assembled with the corresponding components.

Figure 2 - Assembly of the mechanical seal onto the vane shaft.

Figure 4 - Setup of pressurised leakage test for the Galin pump using compressed air and hand held drill.

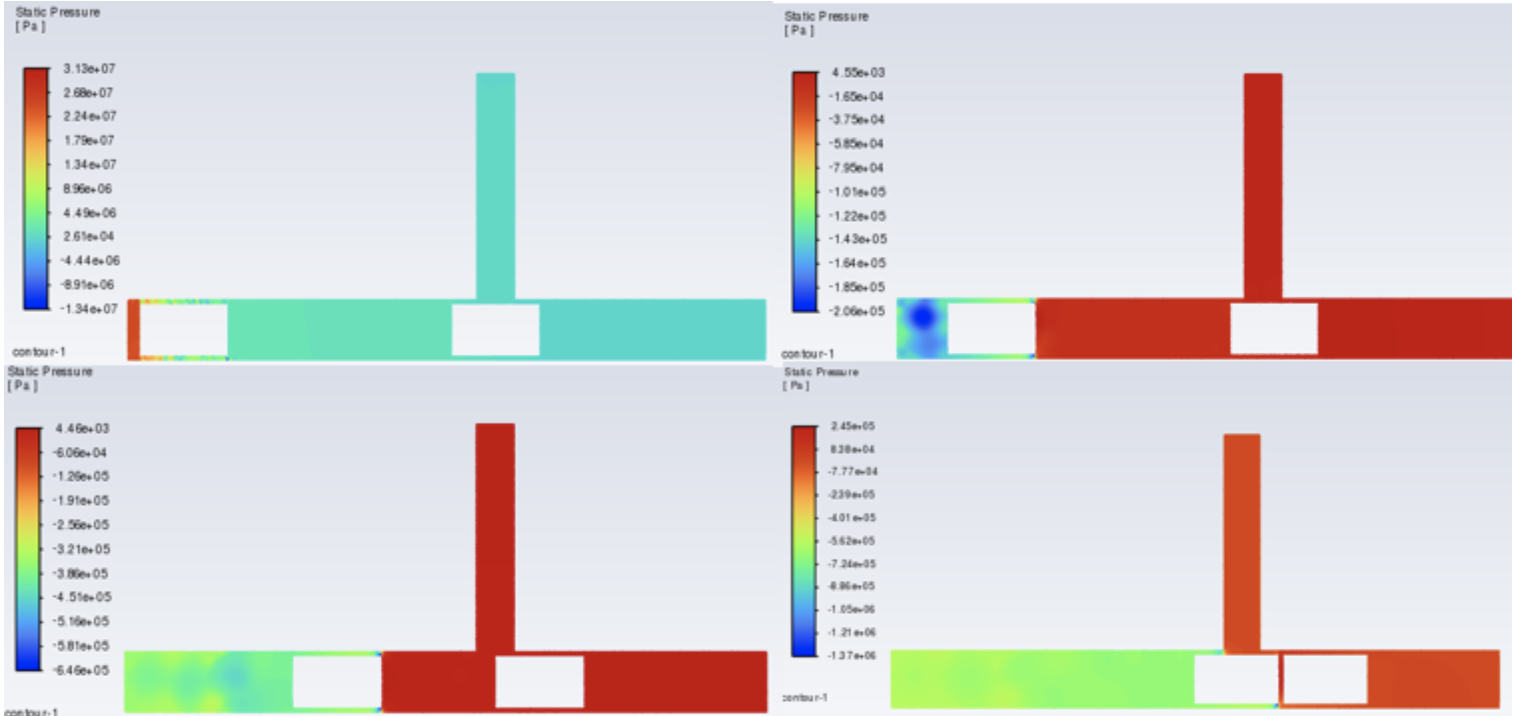

Figure 7 - Stages of the intake and output cycle for the 2D CFD analysis.

Figure 5 - Pressure gauges on the air compressor at 100 psi.

Figure 3 - 3D Galin pump prototype fully assembled with seals and bearings.

Testing involved three key stages. First was the external leakage test: using a hand drill to rotate the vanes at 2000 rpm, while fluid was gravity fed into the pump to assess initial leakage failures. After an initial failure due to shaft dimensional error with 3D printing, a reprint of the vane allowed for successful sealing with zero leaks. The second test assessed internal leakage, which unfortunately revealed that the SLA-printed vane and casing clearances were oversized, allowing near-instantaneous fluid equalisation between chambers. Finally, the maximum pressure test confirmed that the system could handle 100 psi without failure, proving the robustness of the seals and SLA build. The pump and the fluid were pressurised with an air compressor.

Parallel to the physical testing, a 3D CFD simulation in ANSYS Fluent was attempted to study the internal flow of the pump. However, the motion of the dual rotating vanes proved too complex for the timeline and skill set to which, the CFD analysis was pivoted to a simplified 2D simulation of the compression and output cycle of the pump. This required custom coded UDFs to replicate the vane motion, to extract a basic pressure and flow output trend analysis.

Figure 6 - left: the basic 3D fluid domain of Galin pump; middle: the initial velocity results, and right: initial pressure results.

One of the biggest takeaways from this project was just how effective mechanical seals can be, even when paired with imperfect 3D printed parts. Despite some major challenges—like bowed vane shafts and inconsistent diameters due to SLA printing tolerances—the seals held up under 689 kPa of pressure at 2000 rpm with no external leakage. That was a huge win and showed that these types of seals are more robust than expected, especially for prototyping smart pumps. On the flip side, internal leakage was a real issue. The intended 0.2 mm clearances weren’t achieved due to dimensional inaccuracies, which meant the chambers equalised way too quickly. It became clear that while SLA printing offers decent strength and surface finish, it can’t reliably hit the tight tolerances needed without post-machining or another workaround. Finally, the CFD side of the project was an eye-opener. Trying to model the full 3D motion of both vanes turned out to be way too ambitious given the time and software limits, but switching to a simplified 2D simulation still offered some useful insight into how the fluid behaves during compression. While not perfect, it sets up a strong base for future work that can dive deeper into the pump’s dynamics.